Extrusion

Profile Extrusion:

Plastics extrusion is a high volume manufacturing process in which raw plastic materials are melted and formed into a continuous profile. Examples include: pipe/tubing, weather stripping, fence, deck railing, window frames and Siding.

Plastics extrusion commonly uses plastic chips or pellets, which are conveyed into a hopper and gravity fed into the feed screw. The polymer resin is heated to molten state by the combination of heat from heating elements around the barrel and shear heating from the extrusion screw.

The screw forces the resin through a die, forming the resin into the desired shape. Depending on the resin and the needed tolerances, that part is then cooled by various methods including water, air or vacuum as it’s pulled down the line by the puller. At GaMra every part is checked via in-line laser measurement systems to ensure absolute product quality before being cut, reeled or coiled to the customers required lengths before being checked again and packaged.

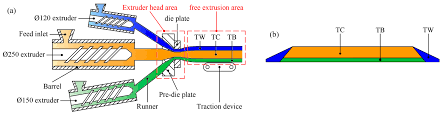

Co-Extrusion and Tri-Extrusion are the processes of extruding two or more materials through a single die with two or more orifices arranged so that the extrudates merge together into a fused single part. Each material (same or different) is fed from a separate extruder. The benefits of doing so is to provide different finishes, soft and rigid materials or other combinations in one cost effective plastic part. Examples might be weather stripping where there is a soft sealing component mated to a rigid holding member for mounting.

The general benefit of the co-extrusion and tri-extrusion process is that every laminate ply imparts a required characteristic property like heat-sealability, stiffness, and impermeability, all of which are impossible to attain by using any single material

Another example might be the vinyl fencing industry, where co-extrusion is used to tailor the layers based on whether they are exposed to the weather or not. Usually a thin layer of compound that contains expensive weather resistant additives are extruded on the outside while the inside has an additive package that is more suited for impact resistance and structural performance.

Co-Extrusion & Tri-Extrusion:

Crosshead Extrusion:

In this process the flow of plastic is typically altered to allow the insertion of a solid material, continuous glass tapes, wire or copper wire to feed into the melt flow to provide reinforcement or strength, and thus become part of the extrusion. Crosshead extrusion is usually used when reinforcements are not able to pass through the machine's barrel and screw.

Crosshead extrusion is typically used to coat plastic over steel cable or jacket multiple tubes to even wires.